Commercial mills plant A1600, A1200, A1000

IMPIANTO: A 700 - A 1000 – A 1200 – A 1600

impianto con trasporto pneumatico

Il trasporto pneumatico serve per tenere pulito il mulino e tiene la farina fredda!

30% piu capacia`oraria!

Tutti mulini sono giralenti che garantisce un ottima qualita`della farina!

al interno in acciaio inox

Importante! Finestre nel setaccio per vedere dentro!

capacità oraria: ca. 180 - 500 kg

Noi facciamo il collegamento del setaccio al mulino tramite il trasporto pneumatico. Il trasporto pneumatico serve per tenere pulito il mulino e tiene la farina fredda! Si aumenta anche la capacita oraria ca 30%

Furthermore, the pneumatic air conveyor system guarantees a constant flow volume of the flour from the mill into the sifting machine. and therefore starve feeding resp. over feeding of the sifter machine can be 100 per cent ruled out, but which could happen because of a varying filling level in a conveyor screw.

Grain mill plant for bakeries

Grain mill with sifter and transport pneumatic.

Grain mill plant

- The grain mill is also available as the smaller model Type A 1200.

- With this grain mill it is possible to produce different sorts of flour and semolina.

- Semolina purifier

- Filter box with air filter bags

- Pneumatic air-conveyor system

- Grain mill Types A 1600 Type A 1200 or Type A 1000

The grounded grain in the mill is transported by a pneumatic air-conveyer to the sieve. In several chambers the flour and semolina is separated in one operation and at the same time the bran is also separated.

In order to increase the share of fine flour, it is possible to take the semolina and grind it again on the finest setting.

To obtain a very white flour the semolina is put into the semolina purifier and is cleaned from the bran particles. Then it is finally ground with the finest setting.

The portion of flour obtained from wheat is approx. 60% to 75% depending on the grinding setting.

In order to produce different types of semolina the sieves can be changed and the mill stones altered. If semolina is needed, then it is necessary to purify it from the bran particles before using it in the semolina purifier machine. The filter box with the air filter bags is for cleaning the conveying air.

Grain mill plant A1200

Grain mill plant with big screen box

Grain mill plant A1200

Grain mill 1600 - base in steel

Mill plant A 700

| Steinmahlwerk | zertifizierte Mahlsteine |

| Gosse, Zarge | aus Kiefernholz |

| Zarge innen | in Nirosta ausgestattet |

| Zahnrad | unerhalb des Trichters |

| Schauglas | im Trichter |

| Regulierung der Mehlfeinheit | mittels Handrad, Magnetfalle |

Untergestell in Metallausführung

Komplett mit Mehlsiebmaschine Type 700

- Ausführung in Kiefernholz mit 3 Kammern

- Mahlkammer innen in Nirosta

- 5 Siebrahmen mit verschiedenen Stärken

und pneumatische Transportanlage

- Zyklon mit Schleuse, Absaugventilator

- Rohrleitung mit Bögen in Nirosta, Filterkasten, Filter

Hulling machine for spelt

Spelling machine with aspiration-system

- Charging hopper and separating device for impurities

- Hulling cylinders

- Adjustment, regulation of cylinders

- Chaff ventilator and the first chaff exhaustion

- Adjusting head of hulling cylinders

- Second chaff exhaustion and dust output

- Separating device for the broken grains

- Outputs of hulled grains of spelt

Industrial mill

Industrial mill

- This equipment complies with all security and health requirements and it is authorized to have the sign “CE”.

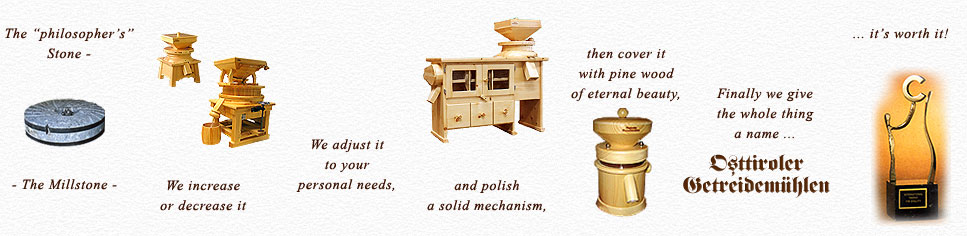

- The Green family is the sole producer of grain mills to be awarded the State Award from the Bavarian State Government.

- We will guide you from the grain to the flour.

- We would be happy to produce an industrial mill tailored to your particular needs.

Osttiroler Getreidemühlen | Heidi Green | A-9991 Dölsach, Muehlenstrasse 2

Tel: +43 (0)4852 61061 | E-Mail: og@getreidemuehlen.com | Contact: Contatto |